Welding Report Shield Metal Arc Welding 1. Besides that the arc and sound will be inconsistently when the welding process been conducted.

Introduction to Welding 2.

Arc welding workshop report. Welding Report Shield Metal Arc Welding 1. WORKSHOP REPORT NAMEAHMAD ZAHID BIN AMRAN IC NUMBER. ENCIK ASRIZAL BIN MOHD AMIN 2.

THEORY ARC WELDINGArc welding is one of several fusion processes for joining metals. By applying intense heat metal at the joint between two parts is caused to intermixdirectly or more commonly with an intermediate molten filler metal. Upon cooling and solidification a metallurgical bond is created.

17093 DCS5038 Chapter 3 88775 Negligence-Part I 94292 Causation-class THE Position OF LAW OF Medical Negligence 98886 Defamation - Lecture notes 12 Integrated VLSI Assignment Report Preview text EME1226 WORKSHOP TECHNOLOGY EXPERIMENT 2. Welding Electric Arc Welding 1 ABSTRACT In the experiment we had to learn how to use arc machine to join. Basic Welding Circuit The arc produces a temperature of about 3600C at the tip and melts part of the metal being welded and part of the electrode.

This produces a pool of molten metal that cools and solidifies behind the electrode as it is moved along the joint. There are two types of electrodes. View report weldingdocx from dcc 5172 at politeknik kota kinabalu.

Polytechnic of kota kinabalu mechanical engineering department djj20042 - mechanical workshop practise 2 report lab sheet arc and. To give a real life experience of metal arc welding to engineering students. To teach the student about the safety in working in welding workshop.

There are 2 types of welding machine. A Alternating Current-AC. This machine is good for use in workshop and farm workshop.

An arc suitable for welding can be either with AC or DC source. The voltage ranges from 15 to 45 volts depending on the welding process. The current for welding may range from 30 to 600 amperes depending on the process and the thickness of material to be welded.

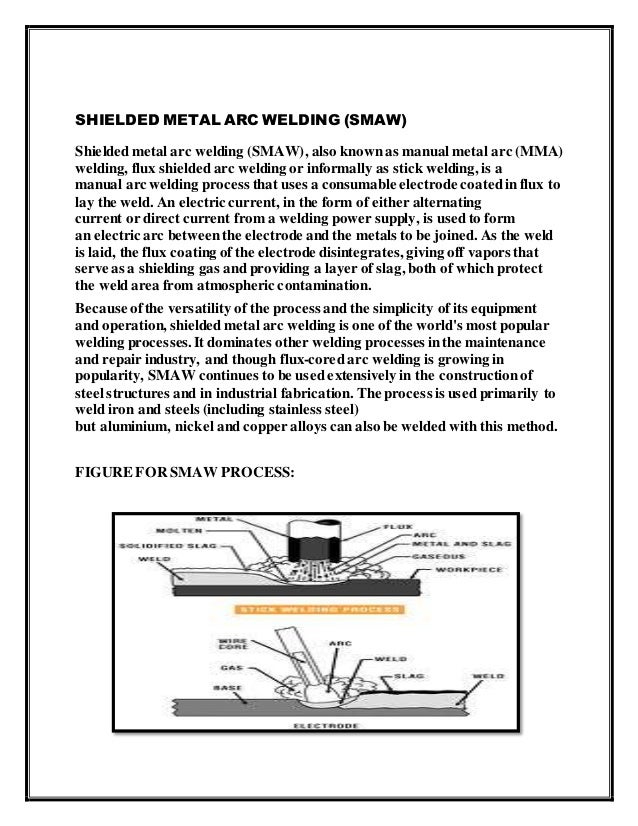

Arc Welding Process In arc welding a welding power supply is used to create an arc between the base metals metals to be welded and electrode. Heat is generated in the base metals causing them to melt and fuse together. The electrode can either be consumable or non-consumable.

A project report on welding of metals. This report will help you to learn about- 1. Introduction to Welding 2.

Classification of Welding Process 3. Symbol and Identification 6. Project Report on the Introduction to Welding Project Report on the Classification of Welding.

The course also includes short arc spray and Fluxcore theory and practice. Aluminum MIG welding is also covered. Review of shop safety practices shop math weld symbols and some blueprint reading are also covered.

Upon satisfactory completion of Course 3 the student should be able to set up the equipment for a specified process weld with. If the arc length is too long the welding will become uneven and some splatter will show. Besides that the arc and sound will be inconsistently when the welding process been conducted.

Other than that the penetration into the base metal is also poor. The electricity-consuming device the key component of the arc welding apparatus is the power source. Electrical consumption from the approximately 110 000 to 130 000 arc welding machines in use in Canada is estimated at 100 GWh a year.

In the past power sources used transformer-rectifier equipment with large step-down transformers. The American Welding Society AWS was founded in 1919 as a nonprofit organization with a global mission to advance the science technology and application of welding and allied joining and cutting processes including brazing soldering and thermal spraying. AWS strives to move the industry forward in both thought and action as well as inspire new generations to see the exciting career.

The Rochester Arc Flame Center RocAFC is the only facility of its kind in the northeast that offers training classes in welding glass smithing and jewelry. RocAFC features instructors who are experienced professionals and nationally-renowned artists to provide the best programs available. Arc welding is a process that is used to join metal to metal by using electricity to create enough heat to melt metal and the melted metals when cool result in a binding of the metals.

Since the joining is an inter-mixture of metals the final weld joint potentially has the same strength properties as the metal of the parts. The report with sketch specifications and applications of pipe fitting tools demonstrated. 02 9 V Prepare pipe fitting jobs as per drawings-two jobs.

04 10 VI Demonstrate use of different welding transformers and consumables. Also demonstrate arc welding gas cutting soldering and brazing operations. American River College is a public community college offering a wide variety of career and transfer programs to students in the greater Sacramento California region.

The global Arc Welding Robots market was growing at a steady rate in 2019 and will reach an anticipated rise at a considerable rate through the end of 2025. According to a market analysis report the global welding products market size was estimated at USD 1449 Billion in 2019 and is projected to register a revenue-based CAGR of 62 over the. The Harris Products Group zero compensated flowmeter regulator for use with shielding gas protects the weld puddle against contamination from atmospheric air and other elements that can cause weld defects.

The device uses a ball float and a variable area flowmeter to yield precise control of the welding gas. The control valve is placed on the upstream side of the flowmeter which means.