The following formula is used for sizing valves for steam service at 10 overpressure. That is theyre using their actual orifice size and their certified flow coefficient.

Control Company a leader in pressure relief valves offers the 4200 Series an ASME Code Section I and VIII certified safety valve.

Asme relief valve sizing. Relief device basics The purpose of relief sizing is to determine the proper discharge area of the relief device and diameter of the asso- ciated inlet and outlet piping. If the relief device is under- sized high pressure and equipment failure may result. Consequently the safety valve would be sized to pass at least 953 kgh when set at 4 bar g.

Once the fault load has been determined it is usually sufficient to size the safety valve using the manufacturers capacity charts. A typical example of a capacity chart is shown in Figure 943. Factory trained Representatives will offer you a choice of solutions for your application utilizing our Computer Valve Sizing Program.

VALVES DESIGN E XCERPTS FROM ASME CODE. Z2122 used nationally for sizing relief valves. The rating is obtained initially on a test tank where 15psi of steam pressure is accumulated.

Under these conditions the thermostat has opened the valve and the steam flows through the orifice into an accumulating tank where it is measured nd tr sl e io v g. Th the safest form of rating relief valves. Relief Valve Sizing for Atmospheric Distillation Column of Crude Oil Refining Process.

The API Standard outlines Standard Orifice Sizes and as shown in Figure 3 FluidFlow has suggested the next closest size match is orifice size R 103 cm 2. This matches the hand calculation. So understand that API and ASME do not have separate methodologies for the final sizing of a valve.

When a vendor sizes a valve for you they are doing a final sizing calculation. That is theyre using their actual orifice size and their certified flow coefficient. When you size a valve using the API orifice sizes and API coefficient youre simply doing a preliminary estimate of the valve size.

Yarway ARC Flow Control Valve Sizing. Tank Vent Sizing for Pressure Relief Valve API 200ISO 28300 or Free Vent API 2000 ISO 28300 6th edition Sizing. Sizing Inputs can be in English or Metric Units for.

Pressures Vacuum and Back Pressures. Valve Selection simplified with Filter Bar Options like. Too often pressure relief valve sizes are determined by merely matching the size of an existing available vessel nozzle or the size of an existing pipe line connection.

Correct and comprehensive pressure relief valve sizing is a complex multi-step process that should follow the. The first step in sizing a Relief Valve in ProMax is to determine which scenario you are interested in modeling. The Relief Valve Sizing in ProMax is performed as a stream analysis.

Any stream in ProMax may have one or more Relief Valve Sizing Analyses added so multiple cases can be studied in a single stream if desired. The following formula is used for sizing valves for steam service at 10 overpressure. This formula is based on the empirical Napier formula for steam flow.

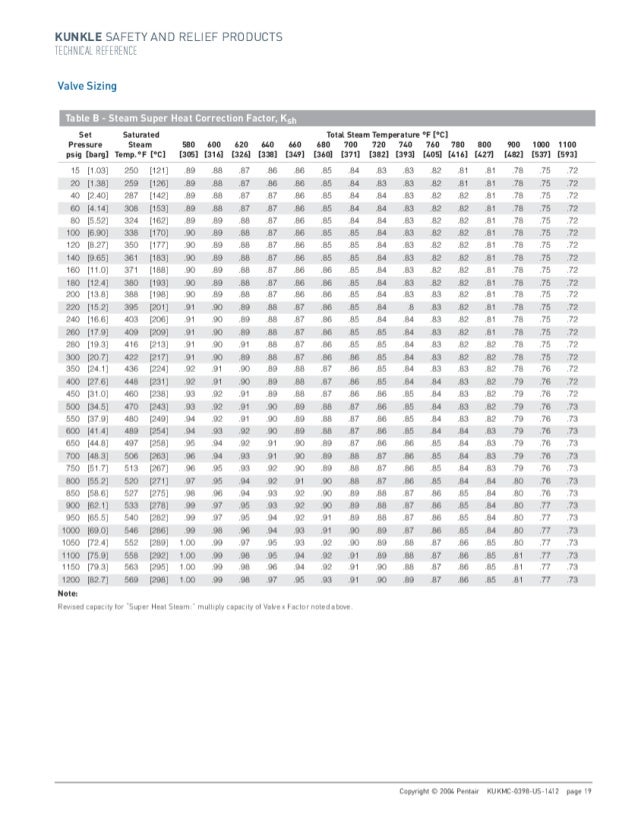

Correction factors are included to account for the effects of superheat back pressure and subcritical flow. An additional correction factor K. Emerson has designed and has available to customers a computer sizing program for pressure relief valves PRV2SIZE Pressure Relief Valve and Vent Sizing Software.

The use of this comprehensive program allows an accurate and documented determination of such parameters as pressure relief valve orifice area and maximum available flow. Determine the required relief loads. Select preliminary valve sizes.

ASME BPVC manages testing reparation and certification of safety relief valves. Most manufacturers have approvals from ASME and PED as they considered as laws. When installing select settings or sizing a safety valve you need to be in accordance with these codes.

Safety relief valve vents in power plants are typically sized by treating steam flow as a perfect gas flow. ANSI B311 and an ASME paper by G. Liao provided the power industry with the guidance for using this approximation.

They were developed to facilitate choosing a relief valve size early in a project and to ensure that the relief valve finally purchased will have a certified capacity that meets or exceeds the required relief capacity. However the differences in capacity between the initial choice of API orifice and the actual ASME orifice can be significant. Initial sizing and valve selection is done using API equations and final valve selection and certification is done using ASME-certified coefficients and capacities.

When sizing a PSV the sizing. Safety Relief Valves Safety Relief Valve Sizing. Spence Engineering sets and tests all valves in accordance with the applicable ASME code and API 527.

Most competitive valves do not meet API 527 leading to premature simmering and leakage causing system problems and premature valve failure. Control Company a leader in pressure relief valves offers the 4200 Series an ASME Code Section I and VIII certified safety valve. The 4200 Series was designed to meet your require-ments for a dependable cost effective high capacity boiler safety valve.

This product is manufactured in our Brecksville Ohio ISO 9001 certified facility. For selecting relief-valve setpoints two limits are considered. The upper limit is decided by considering the MAWP of the vesselequipment being protected.

As per ASME SEC-VIII the relief valve shall not be set higher than MAWP of the vesselequipment being protected. If MAWP isnt known then design pressure shall be considered as MAWP. Our Circle Seal line also offers ASME rated valves in the M5100 ASME series and D500 ASME series with an adjustable range of 50-1200 psig for the M5100 series and 15-150 psig for the D500 series.

Both series are available in your choice of naval brass or 316 stainless steel body materials and a manual override.