How does a centrifugal pump produce pressure. To order or to purchase a new centrifugal pump we need to have some basic information about pumping liquid.

In this paper various kinds of pumps and operational sequences are described.

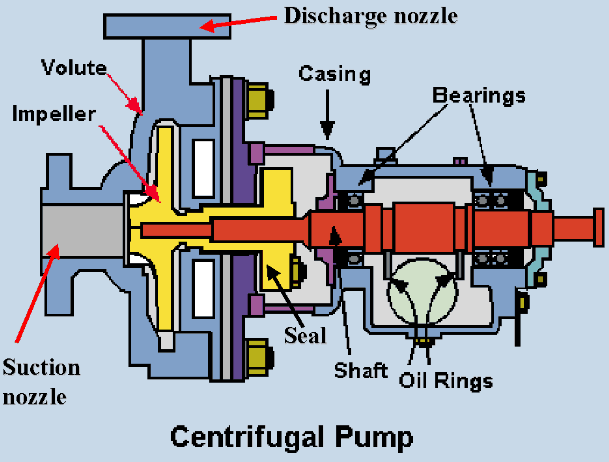

How to design a centrifugal pump. Anzeige High Quality Centrifugal Pump Design with Competitive Price. There are many types of centrifugal pump systems. Figure 1 shows a typical industrial pump system.

There are many variations on this including all kinds of equipment that can be hooked up to these systems that are not shown. A pump after all is only a single component of a process although an important and vital one. The pumps role is to provide sufficient pressure to move the fluid through the.

The steps to follow to select a centrifugal pump are. Determine the flow rate. To size and select a centrifugal pump first determine the flow rate.

If you are a home owner find out which of your uses for water is the biggest consumer. In many cases this will be. Approach for impeller design because until today design of centrifugal pumps is focused on high efficiency performance.

Additional challenge for this project was the application of a drum pump which is a relative small pump with an impeller diameter of about 38 mm. It is known that the design method for such small pump deviates significantly from the standard design process whereas the slip factor is. Thereforeb q 337 DesignofVanesatEntrance.

How does a centrifugal pump produce pressure. Fluid particles enter the pump at the suction flange or connection. They then turn 90 degrees into the impeller and fill up the volume between each impeller vane.

A more detail look at a more realistic cross-section of a closed impeller pump can be seen in Figure 19a. The pump type chosen must correspond to product viscosity product density temperature system pressure material of the pump shearing tendency of the product etc. The pump size must conform to the flow rate pressure speed suction conditons etc.

As a manufacturer and supplier of centrifugal pumps and positive displacement pumps we. The design of a piping system can have an important effect on the successful operation of a centrifugal pump. Such items as pump design suction piping design suction and discharge pipe size and pipe supports must all be carefully considered.

A typical horizontal centrifugal pump installation is illustrated in FigCPP1 CPP2 CPP3. Types of centrifugal pumps. Pumps come in all shapes and sizes to fit the hydraulic requirement of the industry.

Here are just a few common designs. Close-coupled centrifugal pump directly coupled to an electric motor thereby reducing the space requirement. There are three basic sub-types of centrifugal pumps.

Axial Flow Pumps are high flow low pressure pumps which lift fluid in a direction parallel to the impeller shaft. Mixed Flow Pumps are medium flow medium pressure pumps which push fluid out away from the pump shaft at an angle greater than 90. Impeller is designed on the basic of design flow rate pump head and pump specific speed.

So the design data are required to design the centrifugal pump. For design calculation the design parameters are taken as follows. Flow rate Q 000293 m3s Head H 10 m Pump speed n 2900 rpm Design and Performance Analysis of Centrifugal Pump.

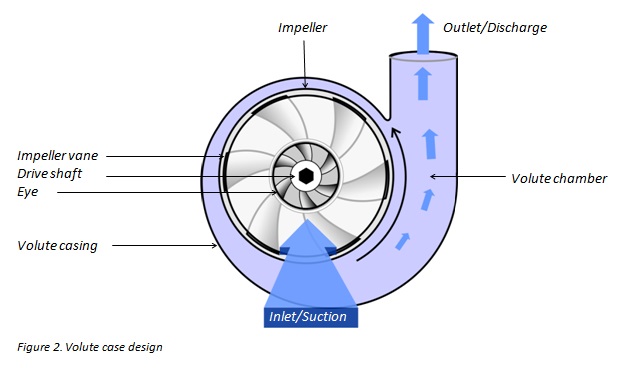

PUMP DESIGN 12Centrifugal Pumps Centrifugal or rotodynamic pumps are based on the principle of imparting kinetic energy to the water. In these pumps water enters axially and is discharged by the rotor into a discharge pipe. They have an impeller which rotates in a casing of a special shape.

Properties necessary for design of a centrifugal pump. To perches a new centrifugal type of pump you need have knowledge of working of centrifugal pumps. To order or to purchase a new centrifugal pump we need to have some basic information about pumping liquid.

The detailed design procedure for volute type pump casing is carried out. In this paper various kinds of pumps and operational sequences are described. And then application and characteristics of centrifugal pump are also expressed.

This paper relates to the design of casing of single-suction centrifugal pump that can develop a head of 30m. Anzeige High Quality Centrifugal Pump Design with Competitive Price.