Before lubing check for a buildup of gunk on the bearing surface. Nor were the oils we used.

Lubricate the right items - place the tiniest drop of light lubrication oil onto all the bearings pivots and sliders including the motor bearings.

Lubricating model train engines. Model Locomotive Maintenance. LubricationHello - Im SamHeres my first instructional video on how to lubricate a 00 locomotive. Although there are many vid.

Instead use a dedicated model train lubricant such as Gaugemasters lubrication fluid or Labelle oil and greases and your engines and rolling stock will run smoother longer and more reliably. Get my recommended Labelle oil. All good suggestions.

I use a light oil on bearing surfaces. Metal gears require a heavier gear lubricant. I would strongly suggest plastic compatible lubricants since most if not all have plastic near the point lubed.

An inexpensive lube is synthetic 5 weight auto lube. Before lubing check for a buildup of gunk on the bearing surface. And over the years have given Labelle glowing reviews as to quality and efficiency of lubricating model trains.

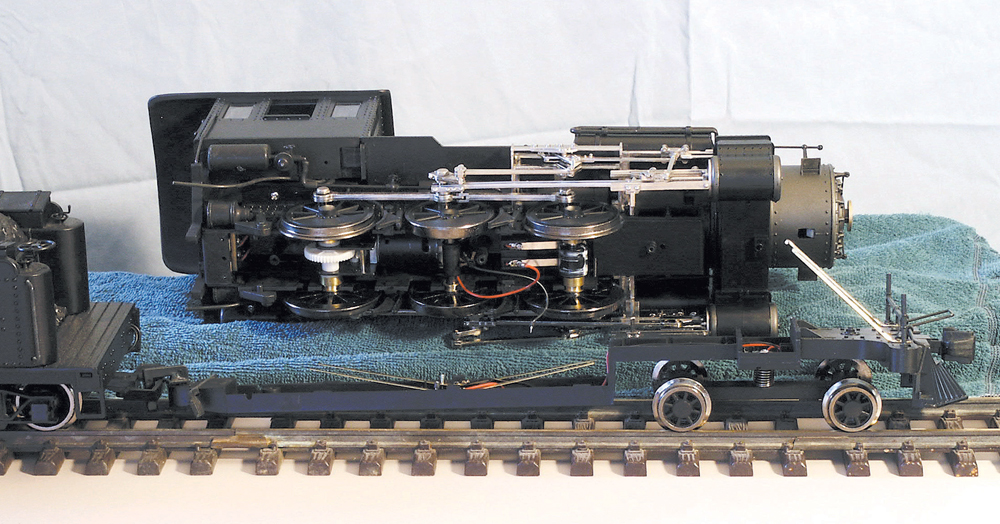

Your expensive model trains need a dependable and time tested lubricants to keep them running smoothly especially when using DCC controllers. Labelle-Lubricants have been the 1 seller in Hobby and Model shops selling model trains for over 43 YEARS And we have sold almost 1000000 model train lubricants. Steam Loco specific – A light oil like Labelle 103 does very good for the moving parts siderods crankpinsvalve gear etc - just make sure it is plastic compatible.

Any loco – light oil on the motor wheel bearings and a light grease inon the gears - again make sure that it is plastic compatible. Since I was just lubing my HO scale engines today. I am using Labelle 106 Plastic Compatible Grease and Labelle 107 Synthetic Light Motor Oil Medium Weight.

These are recommended my name and number for Walthers HO scale Trainline Locomotives in their instructions. The back of the Labelle package of grease says use 108 Oil for N scale. As long as you do not use stuff like WD40Marvel Oil3inOne on your model trains you should be good.

The 2 key item is do NOT over lube your models. A little oil goes a long way. I only oil when I hear a squeak from the engine.

New engines get a tear down in the first year and the gear boxes are cleaned out and filled with 106. The lubricant you need depends upon the design of the power train in a model. Normally there are two distinct requirements oil for metal to metal bearings and grease for metal to metal gears.

Plastic gears do not require lubricating normally however manufacturers do grease them in order to make them quieter. Model Railroader is the worlds largest magazine on model trains and model railroad layouts. We feature beginner and advanced help on all model railroading scales including layout track plans model railroad product reviews model train news and model railroad forums.

It has a low viscosity that is relatively constant over a broad temperature range so whether cold or hot its viscosity is about the same. It will not gum up it is compatible with plastics metals and paint. You can wipe it up with a tissue if you get it on the painted surface of your model.

The first step in maintaining locomotive engines involves lubricating their components properly by applying model train oil to any movable parts. If the hobbyist can see the oil on each part then it probably means that he or she added too much. A short tutorial and some advice on how I lubricate locomotives.

DO NOT use WD40. Based on my above analysis I use Labelle lubricants and ATF on my model trains. My personal gut feel is that ATF is not fine enough for motor bearings in my tiny HO and HOn3 engines so I use Labelle there.

For gears and similar applications Ill use either the Labelle grease or. Lubricating Oiling and Greasing Locomotives. Posted on October 9 2017.

As well as 3D printing model trains and building model railroads I do a lot of repairs to locomotives for fellow modelers. These range from simple wire repairs up to total motor and chassis rebuilds or replacements. One of the issues I come across is over lubricated.

Back in the early days of model engine design and production metals machining and design simply werent as good as they are today. Nor were the oils we used. This meant that very high oil ratios 20 were always recommended to provide a suitable safety-margin against engine damage.

But things are different today. How To Maintain and lubricate Lionel 0 gauge model train engine video. Easy to do preventative maintenance on your locomotive.

Remove any oil and dirt from the motor commutator and especially from between the commutator segments. Lubricate the right items - place the tiniest drop of light lubrication oil onto all the bearings pivots and sliders including the motor bearings. As far a 3 in 1 oil is concernedIts OK for prewar and postwar metal to metal areas requiring oilI prefer Labelle lubricants and lithium based greases for modern era trains.