With the fast and easy feasibility module users can analyze parts in seconds to predict formability early in the product development cycle. Our experience enables us to quickly and efficiently clear any roadblocks and provide you with sound and effective products and tools according to your specifications.

Incremental forming simulation software platforms addresses these operations with a series of one-step stamping operations that simulate the forming process one step at a time.

Metal stamping simulation software. Sheet metal forming simulation software - Stampack GmbH Sheet metal forming simulation for tool designers Stampack provides fast easy-to-use and affordable solutions to virtually try out sheet metal forming processes. The usage of Stampack optimizes the part production and reduces the time to market significantly. ESI PAM-STAMP gives you the ability to address sheet metal formability challenges from the design of parts and tooling to part production with a single tool.

Validate the forming of individual panels and even help validate the assembly of closure panels such as doors. Develop and validate key manufacturing and joining processes virtually to assure production capability of parts sub-assemblies and assemblies for all sheet metal parts simple to complex conventional steel. Benefits of Metal Stamping Simulation Software.

Simulation software has proved to be a boon to metal stamping industries in our time. There are many industries like aeronautics electrical electronic automotive and so on that benefit from this aid. The metal stamping software is used to get an overall idea about how the part will work the best design and also helps build the required tool to.

Inspire Form is a complete stamping simulation environment that can effectively be used by product designers and process engineers to optimize designs simulate robust manufacturing and reduce material costs. With the fast and easy feasibility module users can analyze parts in seconds to predict formability early in the product development cycle. With an all-new user interface the Dynaform 60 die system simulation software enables users to quickly conduct sheet metal stamping simulations to estimate the blank cost and formability of stamping parts via guided process wizards.

The Development of AutoForm Software. In the early 2000s I came across AutoForm software. This software had an entirely different approach and method for accurately solving sheet metal forming simulation problems.

The most notable of which was the complete automation of the tool geometry meshing phase an incredibly robust meshsolver combination that requires basically no further. QForm is a professional engineering software used for simulation analysis and optimization of metal forming processes providing excellent reliability. It covers the essential needs in metal forming simulation for large and small manufacturing companies as.

Software Solutions for Sheet Metal Forming and BiW Assembly AutoForms software solutions form a comprehensive platform for the engineering evaluation and improvement of the sheet metal forming and BiW assembly processes. Designed for everyday real life applications our software solutions increase engineering throughput and ensure optimal part production. In metal forming simulation the forming of sheet metal is simulated on the computer with the help of special software.

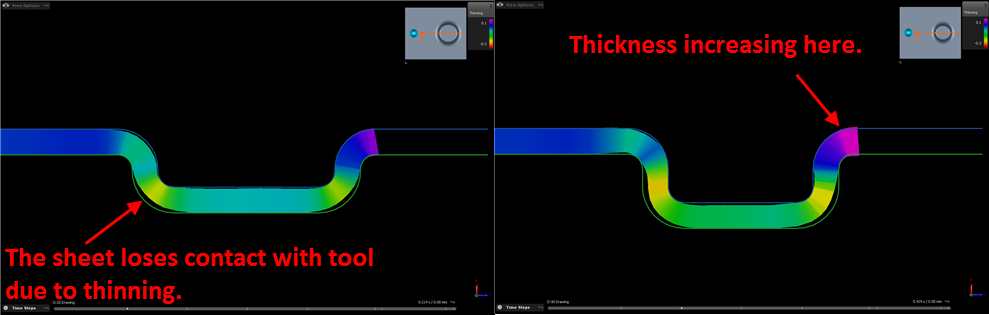

Simulation makes it possible to detect errors and problems such as wrinkles or splits in parts on the computer at an early stage in forming. In this way it is not necessary to produce real tools to run practical tests. Forming simulation has become established in the automotive industry since it is used to develop and optimize every sheet metal.

StampingSimulation has been in the forming simulation business for over a decade. Our experience enables us to quickly and efficiently clear any roadblocks and provide you with sound and effective products and tools according to your specifications. We are engineers serving engineers and we know your customers can be very demanding.

This is why our engineering base works on a follow the sun. Stamping simulation allows the forming process of any sheet metal part to be simulated using software so sheet metal part designers and toolmakers can avoid the expense of making a physical tool by using stamping simulation to discover how likely successful manufacture of a sheet metal part is. Press Line Simulation from Siemens is an innovative software tool for the comprehensive programming analysis and simulation of multistage presses.

The digital simulation of the entire sheet-metal stamping process permits preplanning and virtual optimization of all processes at the start of the planning phase. Stamping simulation software 3D SHELL Stamping with Stampack allows the full manufacturing process validation starting with the blank format including gravity effects binder wrap drawing trimming re-striking repositioning and flanging. Founded in 1989 Forming Technologies FTI is the worlds leading provider of software solutions for the design feasibility and costing of sheet metal components.

Information for customers in relation to the COVID-19 coronavirus outbreak. Founded in 1989 Forming Technologies FTI is the worlds leading provider of software solutions for the design feasibility and costing of sheet metal components. Learn More ABOUT US.

Incremental forming simulation software platforms addresses these operations with a series of one-step stamping operations that simulate the forming process one step at a time. 8 Another common goal in design of metal forming operations is to design the shape of the initial blank so that the final formed part requires few or no cutting operations to match the design geometry. Sheet Metal Forming Simulation with Pam Stamp.

If playback doesnt begin shortly try restarting your device.