If the packet withstands the test it is declared as pass. To determine the tensile strength of plastic bag handle grip a plastic bag handle with dedicated grips and pull it to break with a force gauge.

The tensile strength was very close to that of commercial plastic bags.

Testing tensile strength of plastic bags. Making the method of attachment of no consequence. Tensile strength is measured in forcecross-sectional area allowing one to make accurate comparisons of different samples. In order to do this one needs to either calculate the cross-sectional area or use the same cross-sectional area for each sample being tested.

Plastic bags represent a film of fairly uniform thickness allowing an accurate. To determine the tensile strength of plastic bag handle grip a plastic bag handle with dedicated grips and pull it to break with a force gauge. Tensile Strength Test of Plastic Bag Handle.

To determine the tensile strength of plastic bag handle grip a plastic bag handle with dedicated grips and pull it to break with a force gauge. IMADA offers the dedicated testing system such as the following configuration which is utilized in quality control and RD. Tensile Property Testing of Plastics Ultimate Tensile Strength.

The ability to resist breaking under tensile stress is one of the most important and widely measured properties of materials used in structural applications. The force per unit area MPa or psi required to break a material in such a manner is the ultimate tensile strength or tensile strength at break. The rate at which a sample.

Determined the tensile strength of the bioplastic the force that enters the test computer before the force. The elongation property should be improved in order to be utilized for plastic bags. This decrease in tensile strength was attributed to the weakening of the interface between the bioplastic matrix and the wood fibers singh 2007.

Ultimate tensile strength uts test demonstration. To determine the tensile strength of plastic bag handle grip a plastic bag handle with dedicated grips and pull it to break with a. Optimization of corn was obtained.

The tensile strength was very close to that of commercial plastic bags. Their promotion has however never been closer to real practice than with the collaborative project. D-Optimaly response was obtained by the value of the desirability function.

The optimal conditions were 05 ml glycerin and 472 g corn starch with a tensile strength of 1718 Mpa. To determine the strength of a particular type of bag for example plastic bags and exactly how much the strength increases when multiple bags are used. Take a plastic bag and fill it with stuff until it breaks.

Now take two more plastic bags just like the first one insert one inside the other and fill that inner bag up with the same amount of stuff that broke the first bag. Tensile testing of thin plastic sheets is done to determine how the plastic material stretches or strains when pulled by a large load. Mechanical properties of thin plastic sheets such as tensile strength and elongation are determined for design purposes and product comparison.

Tensile strength of plastic sheets is the measure of how a plastic film responds to being pull. For applications that use thin sheet. Tensile Testers Labthink Instruments Co Ltd.

144 Wuyingshan Road Jinan PRChina 250031 Phone. Open the catalog to page 1. Applications Plastic films composite materials soft package materials plastic flexible tube adhesives adhesive tape label stickers medical.

Dart Impact Testers To test the Impact Resistance of Plastic Films Dart impact strength determines the resistance of the plastic films against the free falling of blunt object on the packet. In this test a predefined load is made to fall on the packet using a missile style dart. If the packet withstands the test it is declared as pass.

This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment temperature humidity and testing machine speed. Touchstone is also able to perform the technically equivalent method ISO 527-1 Determination of Tensile properties of Plastics. For the mechanical properties the highest tensile strength and tensile modulus was achieved for Sample 10 which contain 4wt cellulose 2434wt MMT and 93566wt of PLA.

The strength generated. Our Tensile Strength Tester are used in HDPE and PP bag testing. Tensile Strength Tester is based on constant rate of traverse principle in which one end of the test specimen is held in a stationary grip while the other end is made to move at a known fixed speed with the help of motor gear box and screw arrangement.

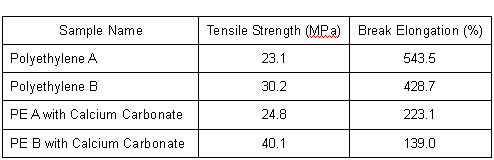

Polyethylene Plastics Testing. Polyhedron Laboratories specializes in a variety of polyethylene analysis and testing services. Polyethylene plastic polyethene or polymethylene is the most widely used plastic in the world carrying an annual production rate of approximately 80 million metric tons.

Its primary use is in various packaging products such as plastic shopping bags and plastic food containers.